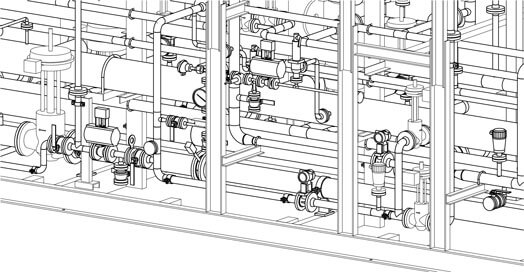

Plant engineering for syngas related gas generation and purification, waste incineration and process steam technologies

The CALORIC plant engineering expertise encompasses a broad and diverse range of process and construction technologies for the chemical and the pharmaceutical industry. From first studies to detailed engineering packages, its scope is addressed to the following fields:

- Hydrogen generation plants

- Syngas generation plants

- Carbon monoxide generating plants

- Gas sweetening plants

- Gas purification plants

- Waste incineration plants

- Pilot and Demonstration Plants

Plant engineering with CALORIC

CALORIC offers sophisticated engineering services, starting with laboratory and pilot testing to detailed engineering design, manufacturing and supervision of plant installation and commissioning. As a result, CALORIC has the capabilities to offer quality industrial processing know-how to a range of industries on a global scale. With more than 500 installed plants worldwide, CALORIC’s proven experience in plant engineering has been developed through proprietary designs and international patents for worldwide leading technology.

Our plant engineering services include:

- Offer Stage / Feasibility Study / FEED Study

- Process Development

- Process Package

- Basic Engineering Package

- Detail Engineering Package

Efficient and comprehensive plant engineering services can be executed exclusively by CALORIC, as all major engineering disciplines are represented within CALORICs inhouse expertise. This is supported by cost efficient and verified process software.

Plant engineering for:

- Reforming plants, incinerators: In-house developed process simulation tools

- Waste Heat Management Systems: PPSD

- Pressure Vessels PED/ASME: DIMy

- Standard process simulation (e.g. gas washing): ProMax

To support the implementation of CALORIC’s plant engineering services into operating plants various means of support from inspection and supervision to turnkey installations are available.

Control systems and their software are increasingly important for maximum plant control and efficiency to convert into lowest OPEX. CALORIC is constantly investing in improving the control software in order to implement its experience from process technologies.

Caloric Anlagenbau GmbH

Caloric Anlagenbau GmbH