Plant revamping and plant modernization

The revamping or re-structuring of existing plants is a preferred economic solution for almost every branch of today’s industries. The revamping process allows companies to modernize infrastructures or to improve product features and increase overall plant capacity. Plant revamping can also mean modifications made to a process for the purpose of changing the operation or the production. During the revamping process, plant’s life circles are extended considerably by applying individual measures and steps to obtain the appropriate solution, while financial efforts and production interruptions are reduced to an economically feasible minimum.

Reasons for plant revamping and plant re-structuring:

- Increase of performance and efficiency

- Reduction of production costs

- Plant lifetime extension

- Optimization of energy consumption and quality parameters

- Simplification of maintenance and management

- Increase of environmental safety

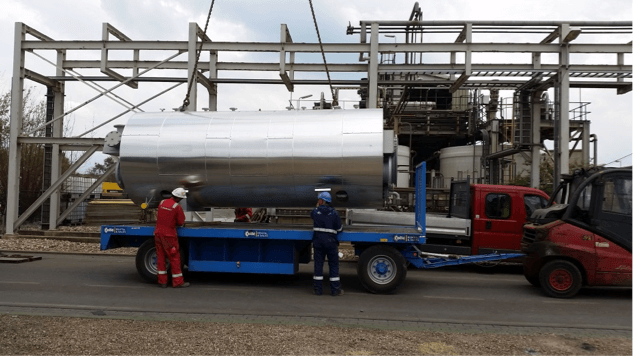

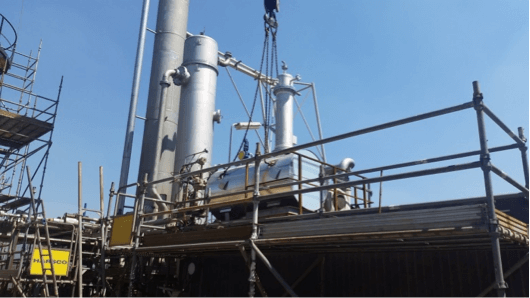

Plant Revamping by CALORIC

Whether due to upcoming bottlenecking situations in the production process, operational or technological reasons: When it comes to significant revamping in a plant’s infrastructure, profound expertise and know-how is a must. CALORIC Anlagenbau GmbH, with more than 50 years of experience in the design and manufacturing of gas generating plants for the chemical and pharmaceutical industries, is your reliable partner for the comprehensive and sustainable renovation of existing plants.

Including the realization of very complex plant modifications, our engineers are experts and in charge of all necessary measures. Thus, our customers do not only benefit from a thoroughly execution and profound technological know-how. They also can be sure to obtain the best available solution for their individual requirements when it comes to plant revamping and plant modernization around the technologies within our portfolio.

Our services

- Comprehensive onsite survey

- FEED study to find appropriate technical solutions

- Budget calculation of all steps, from engineering to plant start-up

- Equipment delivery

- Installation supervision

- Commissioning and start-up supervision

Caloric Anlagenbau GmbH

Caloric Anlagenbau GmbH