Hydrogen by Pressure Swing Adsorption (PSA)

Hydrogen by Pressure Swing Adsorption (PSA)

With the HP process, gases with a considerable content of hydrogen are purified into high purity hydrogen by pressure swing adsorption (PSA). The HP process is designed for hydrogen production at highest efficiency from various raw gases within different industries, eg. refining, (petro)chemical, oil and food, fatty acids or steel-making.

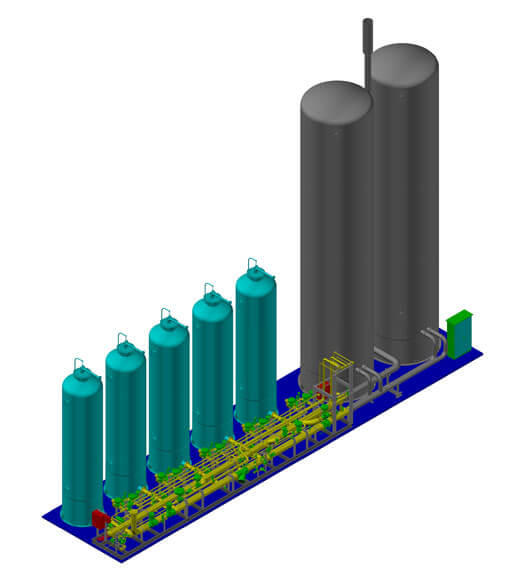

Within CALORIC HP process the PSA can be designed either with 4, 5 or 6 adsorber vessels, depending on customer requirements and their focus on optimisation for process efficiency, on-stream time, investment and operational costs.

The PSA will be designed according to CALORIC’s well established skid mounted, modular design (design concept). The PSA will be pre-manufactured in CALORIC’s workshop and tested before delivery. Such design and manufacturing approach will secure shortest re-erection at site and savings in reduced time and costs required on-site to put the plant into operation, compared to “loose item” delivery.

Facts

Typical feed:

hydrogen-rich gases

Capacity range:

50 – 20,000+ Nm³/h

H2 purity:

typically 99.999% by vol.

(optional 99.9999% by vol.)

H2 supply pressure:

typically 15 bar (g) to 25 bar (g)

Operation:

automatic, PLC controlled

Caloric Anlagenbau GmbH

Caloric Anlagenbau GmbH