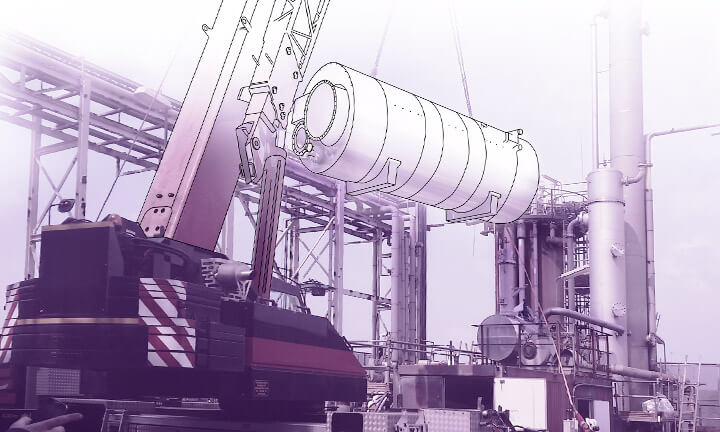

Plant revamping and plant modernization The revamping or re-structuring of existing plants is a preferred economic solution for almost every branch of today’s industries. The revamping process allows companies to modernize infrastructures or to improve product features and increase overall plant capacity. Plant revamping can also mean modifications made to a process for the purpose

Read MoreHydrogen by Pressure Swing Adsorption (PSA) With the HP process, gases with a considerable content of hydrogen are purified into high purity hydrogen by pressure swing adsorption (PSA). The HP process is designed for hydrogen production at highest efficiency from various raw gases within different industries, eg. refining, (petro)chemical, oil and food, fatty acids or

Read MoreSyngas CALORIC has developed and supplied syngas generating plants based on the steam reforming HC process, the MeOH reforming HM process or the CALCOR CO generation process. Depending on the required H2 to CO ratio, purity requirements and feed situation, various plant configurations are possible. Typically, the process is close to the standard reforming processes.

Read MoreHYDROGEN BY STEAM REFORMING With the HC process, high purity hydrogen is produced by steam reforming of a hydrocarbon combined with a PSA purification step. The feed is mixed with a split stream of hydrogen and then preheated in the heat exchanger prior to passing a sulphur removal. The feed is then mixed with superheated

Read MoreHydrogen by Methanol Reforming With the HM process, high purity hydrogen is produced by methanol reforming combined with a PSA purification step. A mixture of methanol and demineralised water is vaporised in heat exchangers. Whilst passing the heated catalyst, the methanol/water vapour mixture is converted into a syngas consisting of H2, CO, CO2, CH4 and

Read MoreHydrogen by Dual Feedstock / Multi Feedstock Plants Under normal market situation, the most efficient feed for a low OPEX hydrogen generation plant is natural gas. However, in some world regions the supply is insecure due to network pressure drops or natural gas price is extremely high as only LNG is available. Alternative feedstocks then

Read MoreMembrane Purification With the HPM process, gases with a considerable content of valuable gas are purified by using highly selective membranes. The HPM process is designed for gas production at highest efficiency from various raw gases within different industries, eg. refining, (petro)chemical, oil and food, fatty acids or steel-making. Within CALORIC HPM process the membranes

Read MoreGas to Liquid (GtL) The CALORIC reforming technologies provide optimized syngas generation systems capable to handle associated and stranded gas for GtL plants. Furthermore GtL plants provide specific challenges which are met by the well proven CALORIC reforming processes. Efficient process designs for low operating costs to provide syngas suitable for production of gasoline, methanol

Read MoreGeneral Information about Waste Heat Management System CALORIC has acquired in-depth know-how on waste heat management systems with the implementation of steam boilers into syngas generating plants and into hazardous waste incinerators. Heat capacities from 0.1 MW to 7.0 MW have been installed in CALORICs plants, converting heat from a variety of gases and gas

Read MorePilot and Demonstration Plants In almost every industry, pilot plants and demonstration plants play a key role in filling the gap between the conceptual engineering phase and commercial production. While the early stages of process development and front end projects are crucial for the success of new industrial plants, the design of pilot and demonstration

Read More Caloric Anlagenbau GmbH

Caloric Anlagenbau GmbH